The game of baseball is steeped in tradition and history, right down to the design of each and every piece of equipment. Take, for example, the ball itself – quite literally a stitch in time! From its unique construction to its distinct six-pointed stitching pattern, the baseball has become one of American culture’s most iconic sports artifacts. But how many stitches are truly on a baseball? In this blog post, we’ll delve into some interesting facts about why so many stitches are necessary for creating a regulation for Major League Baseball and explore what goes into making an official MLB caliber ball. So grab your bats (or whatever you play with!) and let’s dive into our look at how many stitches there really are on a baseball!

How Many Stitches Are on a Baseball?

The number of stitches on a baseball is 108. Each stitch is made up of two interlocked pieces of woolen yarn, with each piece being about 10 inches long. The stitches are arranged in six equal sections, giving the ball its characteristic round shape and allowing it to fly farther when thrown. This is why older baseballs were said to have “deader” centers than modern balls – they didn’t have as many stitches.

The number of stitches on a baseball has remained virtually unchanged for over 100 years and is likely to remain so for the foreseeable future. It’s a testament to the craftsmanship and expertise required to make such an iconic piece of sporting equipment, one that has been enjoyed by millions around the world for generations. [1]

How Does the Number of Stitches Affect Baseball Performance

1. Air Drag

The number of stitches on a baseball affects the amount of air drag that is created when the ball travels through the air. More stitches create more drag which slows down the velocity of the ball and can reduce distances that pitches travel.

2. Spin Ratio

The number of stitches also affects spin ratio, which is how much a pitch spins as it travels through the air. A higher spin ratio makes it easier for pitchers to control their pitch location, making them more successful at getting hitters out. [2]

3. Trajectory

Finally, different stitch counts affect how a given pitch’s trajectory behaves in flight. This can be used to manipulate where a pitcher wants the pitch to go once it reaches home plate but can also make it more difficult for the batter to predict where the pitch will end up. Understanding how stitch counts affect a baseball’s performance can help both pitchers and hitters perform better during games.

Overall, the number of stitches on a baseball affects its performance in many ways. It creates air drag that slows down its speed, it changes spin ratio which helps with pitch control, and it alters trajectory which can make it easier or harder for batters to hit pitches accurately. Knowing how different stitch counts affect ball performance is important for any pitcher or hitter looking to get an edge over their competition. [3]

What Are The Stitches On A Baseball Called?

The stitches on a baseball are known as lacing. The stitching pattern consists of 108 double stitches and is made up of three parts: the horseshoe, long zigzag, and short zigzag. The horseshoe connects the leather panels that make up the cover of the ball, while the two zigzags secure the lining to the inner core. It takes about 25 minutes for a skilled worker to hand stitch one baseball from start to finish.

These laces are made out of waxed red cotton thread that has been treated with beeswax for added strength and durability. This treatment helps them withstand constant wear and tear during games and practice sessions. As an added bonus, it also gives each ball its signature red and white pattern.

The lacing on a baseball is an important part of the game. It helps to keep the ball together and allows pitchers to grip it better, providing more control over their pitches. In addition, it gives batters a better surface for hitting, as the stitches help to create “traction” that makes it easier to hit the ball farther with greater accuracy.

Given its importance in both pitching and batting, having well-made lacing is essential for any Major League Baseball team. By understanding what goes into making each stitch, teams can ensure that they have quality equipment that will last them through multiple seasons of play.

What Is The Purpose Of Baseball Stitches?

The stitches on a baseball are intended to provide the ball with shape, structure, and durability. The construction of a baseball consists of four main parts: an inner core (made from cork, rubber or synthetic material), winding or yarn layers, wool thread binding the seams together and finally, a leather cover. The stitching helps to hold all of these pieces together and provides a more uniform surface for air resistance so that the ball can travel farther when thrown.

Because of this importance, most leagues require that each ball used must adhere to strict standards and be composed of the same materials. This ensures that all players have a fair playing field, as well as that the balls maintain their shape and quality throughout their use. Every major league baseball has 108 stitches surrounding its circumference, however this number can vary depending on the ball’s purpose. For example, some softballs may use fewer or more stitches depending on its intended use.

At the end of the day, these precise stitches help make sure that baseball is played fairly and safely for everyone involved! [4]

Baseball Stitching Process

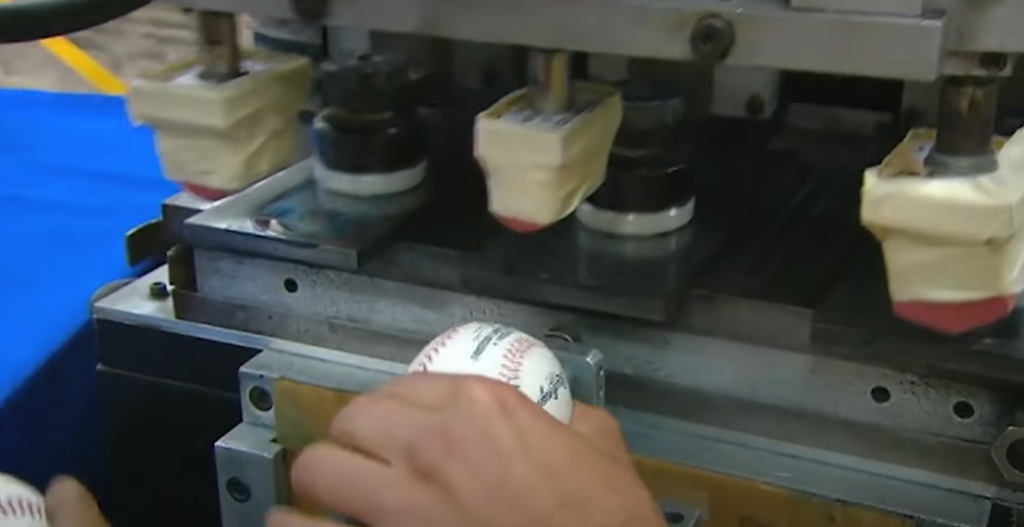

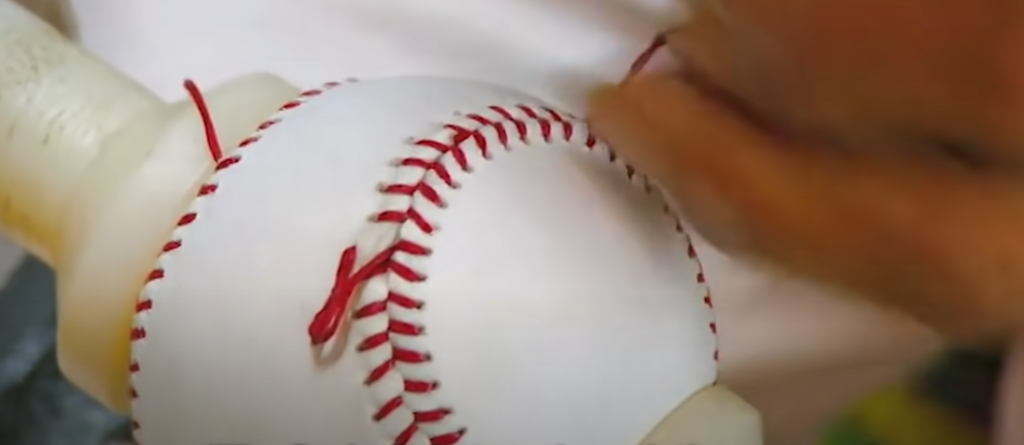

The process of stitching a baseball is a complex craft that involves precise measurements and careful attention to detail. In order to make sure that each ball meets the high standards expected of MLB, the stitching on baseballs must be uniform and consistent. On average, 108 hand-stitched double stitches are used to sew together two pieces of leather when creating a single official MLB baseball. This tight stitch pattern ensures durability so that the ball can withstand repeated pitches, throws and catches during game play. The leather lacing is made from cowhide or horsehide and is tanned with a special oil-based solution in order to make it more resilient.

Typically, there is one small hole at the top of the baseball where the string is inserted before the lacing is looped around the perimeter of the ball. Once all 108 stitches have been sewn, a special wax is applied to the seams in order to further reinforce them and prevent unraveling over time. The stitching process can take up to 2 hours per baseball, meaning that it takes a great deal of skill and precision to create a single official MLB ball.

After being stitched together, each baseball must go through rigorous quality testing in order to make sure that it meets MLB standards. Only after passing inspection will it be approved for game play. Stitching on baseballs has evolved over time as new technologies and materials have allowed manufacturers to produce more durable and consistent balls with fewer defects. With such high stakes riding on every pitch, every throw and every catch, it’s no wonder that so much care goes into the making of each baseball.

Despite the complexity of the stitch process, its importance to the game of baseball cannot be overstated. A properly stitched baseball ensures that players have a consistent playing surface to rely on game after game. Without proper stitching, a ball could quickly become unusable due to tears or unraveling seams.

With every MLB-approved ball having 108 perfect stitches around its circumference, there is no denying that this craft is an essential part of the game we all love. [5]

Why Does Baseball Need To Be Stitched?

Baseball stitching is used for a number of reasons. The main difference between a hand-stitched baseball and one made with anything else is the durability and performance of the ball. Each stitch on a baseball affects the way it travels through the air and reacts with other objects, such as a bat or glove. It also influences how quickly it wears out over time. Without proper stitching, the seams of a baseball can easily unravel, leading to an inconsistent game experience.

Ultimately, proper stitching ensures that your game goes off without a hitch and keeps players safe.

Why Is The Color Of Baseball Stitches Red?

The color of the stitches on a baseball is traditionally red, and this dates back to the introduction of mass-produced baseballs in the early 1900s. The reason for this lies in how those balls were made: they were hand-stitched with red thread because it was much more visible than any other color. This made it easier for both players and spectators alike to track the ball as it traveled through the air. Red also has an association with strength and passion, which makes sense when you consider that baseball is a sport full of spirit and emotion. Today’s baseballs are still stitched by hand using traditional red thread, partly out of respect for its history but also because red remains one of the most visible colors around. [6]

History Of Baseball Stitching

Baseball stitching has a long and interesting history. The first baseballs were handmade, with two pieces of leather stitched together by hand. Up until the mid-1800’s, each team in a game was responsible for making their own balls. In 1855, the National League allowed teams to purchase pre-stitched balls from manufacturers instead of making them by hand. This led to increased standardization among baseballs, and some estimate that the original makers produced about 75-100 stitches per ball during this time period.

By 1915, when Major League Baseball was established as an organization, standardized specifications for baseballs had been developed. Manufacturers followed strict guidelines for production, including requirements for materials and stitching patterns. According to the specifications, each ball should have 108 double stitches, and take between 10-12 minutes to complete.

Today’s baseballs are made with automated machinery that produces perfectly uniform stitching. This guarantees quality control and a much higher stitch count than in the past – around 216 double stitches for a regulation MLB ball! While many of the materials and designs may have changed over time, one thing is certain: there is still a lot of craftsmanship involved in making every single ball used in Major League Baseball games.

How Much Does A Baseball Weigh?

A regulation baseball typically weighs between 5 and 5.25 ounces, or 141 to 149 grams. The core of the ball is usually cork combined with rubber, and it’s covered in two pieces of white cowhide stitched together with red thread. It’s also filled with a set amount of yarn winding that contributes to its overall weight. It’s important for the ball to meet this standard weight as any difference could potentially affect how the ball reacts when it is pitched or hit.

This means that each and every official Major League Baseball must weigh precisely within these parameters before being used in professional play. As such, teams employ workers called “ball doctors” who make sure the balls are up to standard before games begin. So if you ever find yourself asking how much does a baseball weigh, the answer is 5-5.25 ounces or 141-149 grams. That’s why it pays to have an expert on hand to ensure the quality of the ball.

How Often Are Baseballs Replaced During A Game?

The answer to this question depends on the league and type of game being played. Generally, Major League Baseball (MLB) teams replace baseballs with new ones after they are fouled off, thrown out of play, or taken out of circulation for other reasons. Pitchers will typically receive a new ball when the current one is scuffed or soiled. In addition, umpires may call for a new ball if they believe it has been altered in any way. It is estimated that an MLB team goes through about 70 balls per game! Minor league teams also generally follow these rules but may not be as strict; some teams have even been known to reuse slightly scuffed up balls during games! The total number of balls used in a game can vary greatly depending on the number of foul balls and other factors. [7]

FAQ

Are baseballs still stitches by hand?

Yes, baseballs are still stitched by hand. The process is done by skilled craftsmen who use a machine to make small stitches around the circumference of each ball. Each stitch must be perfectly spaced and made with precision in order to ensure that the ball is safe for play. On average, there are 108 double stitches on an official Major League Baseball, which requires about 5 hours of careful work to complete. Professional players often personally thank the craftspeople behind their balls after games as a sign of appreciation for their hard work.

How long do hand-stitched baseballs last?

When properly stored and maintained, hand-stitched baseballs can last for many years – even decades! Various protective coatings have been developed to help preserve the longevity of the stitching, but these coatings can quickly break down if subjected to moisture or dirt. To extend the life of a baseball, it should be kept in its original box and away from extreme temperatures and direct sunlight. Additionally, it is important to avoid contact with rough surfaces as this can cause the stitches to break prematurely.

What type of thread is used for hand-stitching?

Cotton or wool thread is traditionally used for hand-stitching baseballs. This type of thread is strong and resistant to stretching over time, which makes it ideal for use in outdoor sports equipment. It also has a smooth texture that allows it to glide easily through the leather without snagging or tearing. For added durability, threads may also be waxed or lubricated prior to stitching.

Are all baseballs hand-stitched?

No, not all baseballs are hand-stitched. Many modern League balls use a process called “flatseam technology” which eliminates the need for individual stitches. This involves gluing the two layers of leather together with a special adhesive that provides a secure bond and ensures a uniform shape. While this method is faster and cheaper than hand-stitching, it does not provide the same level of quality and durability as traditional methods. As such, most professional leagues still prefer to use handmade baseballs for official games.

Are there 216 stitches on a baseball?

No, the official Major League Baseball has 108 stitches on it. This is made up of two interlocking rows of 54 stitches each. The exact number of stitches may vary depending on the size and model of the ball, but it is usually within a few stitches either way. For example, a smaller baseball such as a softball may have just 96 stitches while some larger balls may have 120 or more.

Useful Video: How Many Stitches Are In A Baseball?

Conclusion

Ultimately, the answer to how many stitches are on a baseball is between 108-108.5. The exact number of stitches varies depending on the league and the size of the baseball. Generally speaking, MLB baseballs contain 108 red cotton threads that form two five-ply yarns, resulting in 108 total strands per ball. Although this may seem like a small detail, it can have a significant impact on how far and accurately a batter can hit a ball. Knowing how many stitches are on a ball is important for athletes and fans alike who want to understand this fascinating game better!

References:

- https://wezen-ball.com/how-many-stitches-are-on-a-baseball/

- https://www.ballqube.com/how-baseballs-are-made/

- https://thestadiumreviews.com/blogs/info/how-many-stitches-are-on-a-baseball/

- https://honestbaseball.com/baseball-stitches/

- https://www.childrensmuseum.org/blog/why-does-baseball-have-red-stitching

- https://www.nations-baseball.com/stitches-on-a-baseball/

- https://www.baseballbible.net/how-many-baseballs-are-used-in-an-mlb-game/

Leave a Review